For years I've used scale 15" alloy wheels on my cars; they're not too wide so they look correct on an American sedan and the Ninco Classic or Ortmann tyres are a good fit. If there was one drawback, it's their price. So using my design skills I had a go at making a cheaper equivalent, and while I was about it I thought I could make them lighter.

The original alloy wheels are 1.8 grammes each, from weighing 20 and dividing them out. The new SLS wheels I've done are 0.6 grammes! Here's how they go together.

This is how they are supplied, SLS is laser sintered nylon which gives an incredibly strong part (much stronger than other types of 3D printing). There's a reamed 3/32" hole for the axle but this is how you install them.

![]()

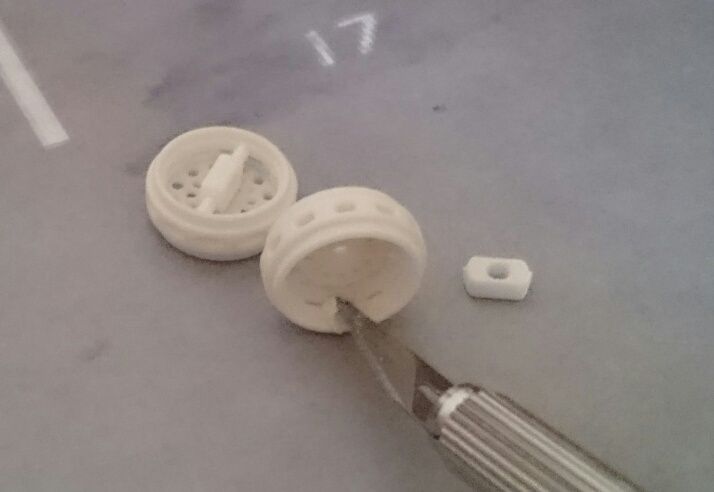

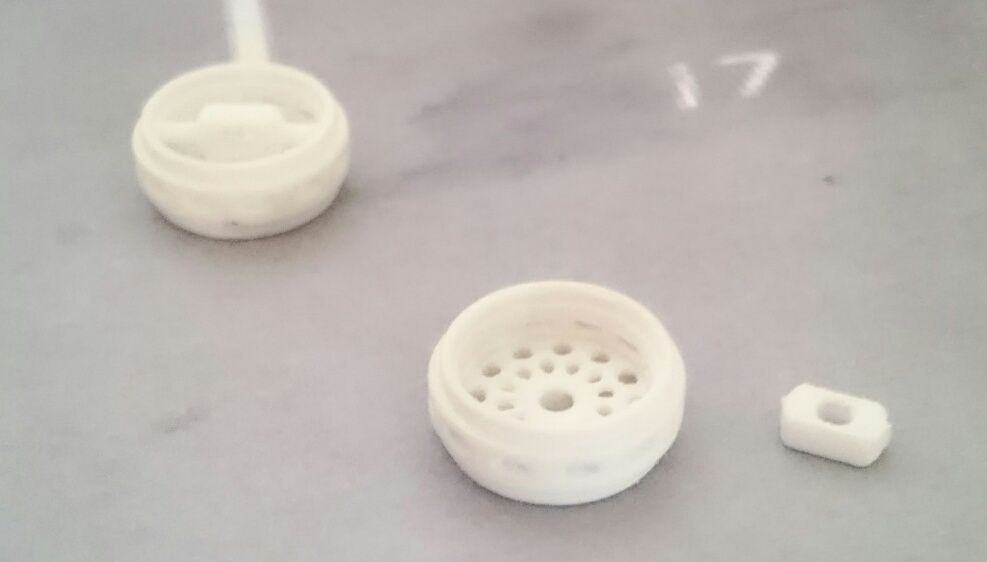

First, cut the spacer out of the middle. This is the "hub" on other wheels and it can be fitted to the rear of the wheel for a wider track if required.

![]()

My go-to tool is a pair of side cutters, but it doesn't give a perfectly flush cut on an internal face so it needs a little trimming.

![]()

A sharp scalpel cuts through it easily.

![]()

A tickle with an old toothbrush removes any trapped powder left during the manufacturing process.

![]()

That's it, they're ready to fit

![]()

You can either glue them to the axle, or there's a hole which will take an M2 grub screw if you prefer.

![]()

If you want them the same dimensions as the alloy wheels, slide the rear spacer into position.

![]()

Ready to go! Fit the resin insert of your choice and take the sense of well-being that comes from saving 5 grammes per car.

![]()

And the price? Instead of £5 a pair, these are £4 a set![smile.gif]()

The original alloy wheels are 1.8 grammes each, from weighing 20 and dividing them out. The new SLS wheels I've done are 0.6 grammes! Here's how they go together.

This is how they are supplied, SLS is laser sintered nylon which gives an incredibly strong part (much stronger than other types of 3D printing). There's a reamed 3/32" hole for the axle but this is how you install them.

First, cut the spacer out of the middle. This is the "hub" on other wheels and it can be fitted to the rear of the wheel for a wider track if required.

My go-to tool is a pair of side cutters, but it doesn't give a perfectly flush cut on an internal face so it needs a little trimming.

A sharp scalpel cuts through it easily.

A tickle with an old toothbrush removes any trapped powder left during the manufacturing process.

That's it, they're ready to fit

You can either glue them to the axle, or there's a hole which will take an M2 grub screw if you prefer.

If you want them the same dimensions as the alloy wheels, slide the rear spacer into position.

Ready to go! Fit the resin insert of your choice and take the sense of well-being that comes from saving 5 grammes per car.

And the price? Instead of £5 a pair, these are £4 a set