Hi guys,

I recently finished this build for the GVSCC Targa Florio proxy race, in Vancouver, Canada.

Im a huge fan of the Porsche 908/03, mainly because back in 2008, aged 14, I saw this build from Jairus Watson Here, and fell in love! Because of this build, I started to learn more about the Targa, and the men who risked everything to win.

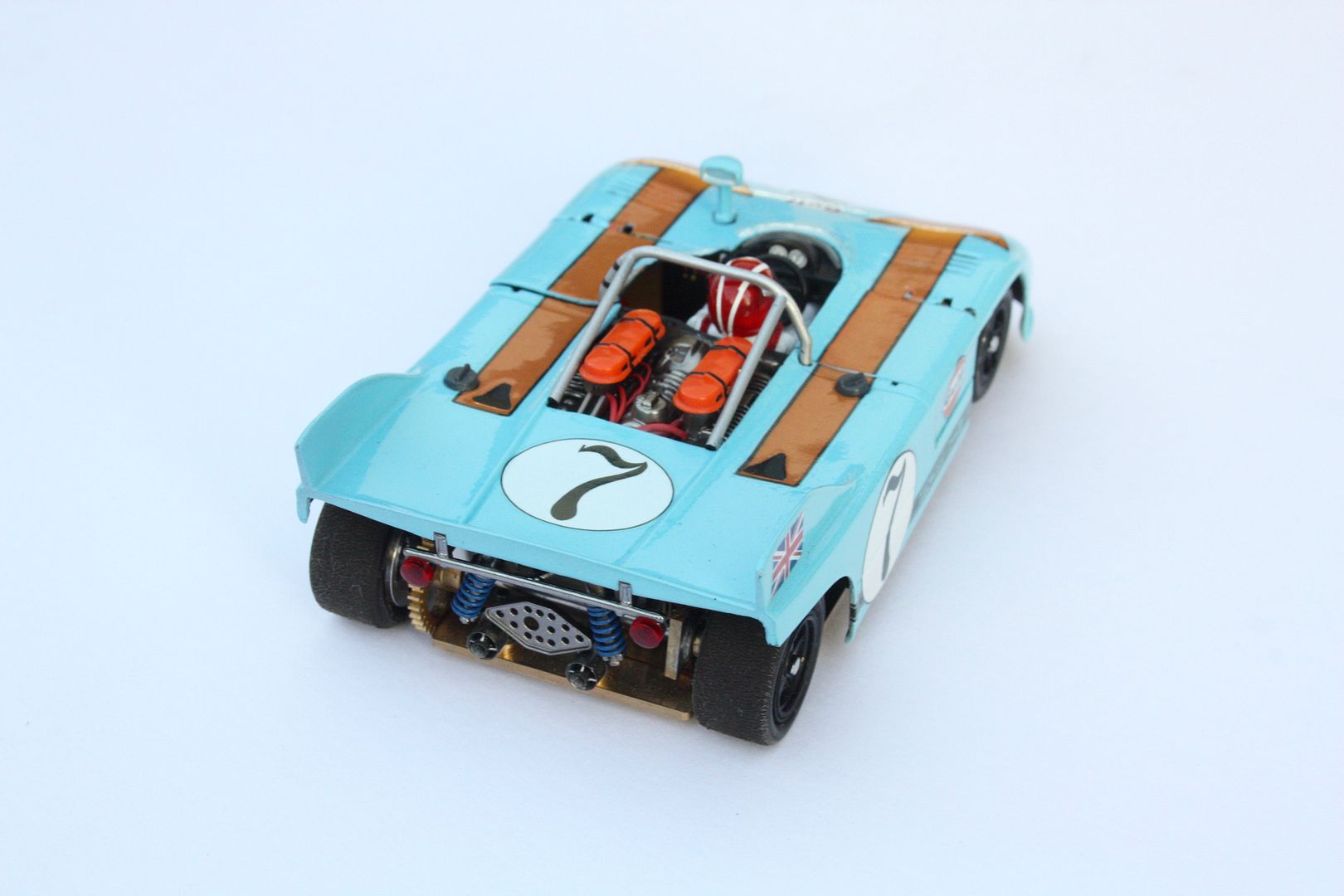

When I read the rules for the proxy, this was the car I had to do. Firstly, I took a Fly Porsche, stripped it down and weighed it. With the bare body coming in at a hefty 20g, I took a mould, and cast a fibreglass body, weighing when cleaned up just 5grammes.

![]()

![]()

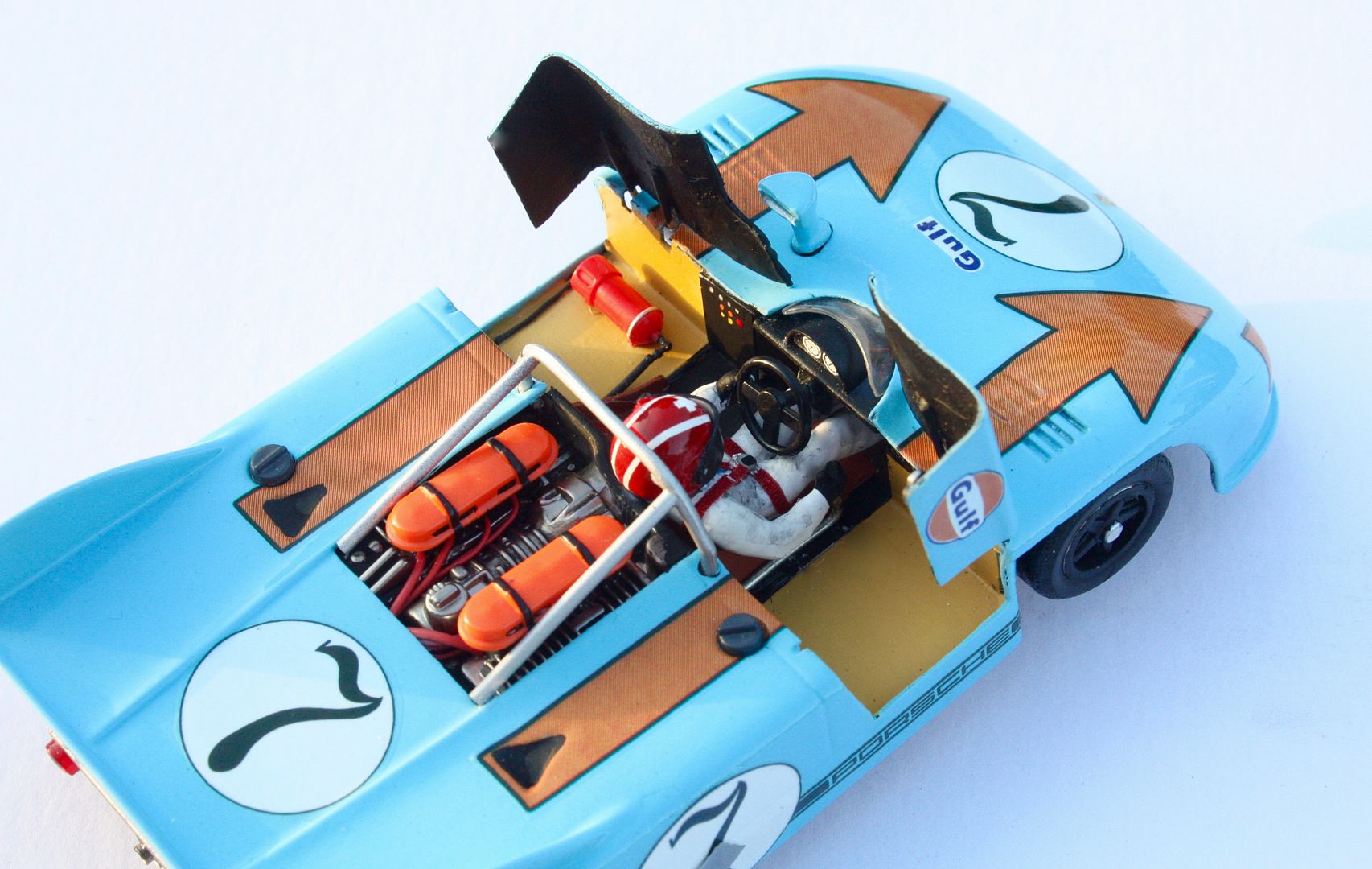

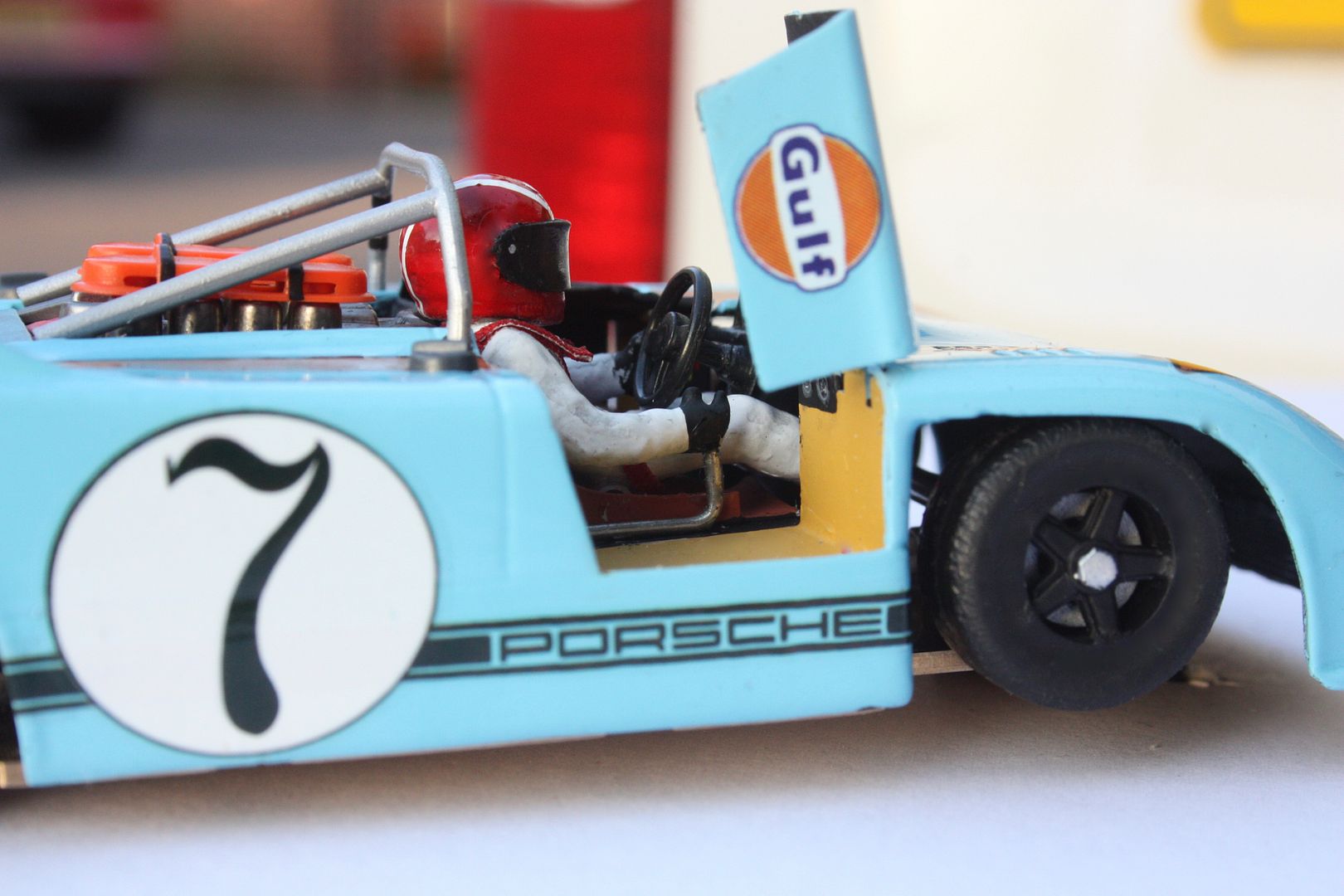

The rest of the build was quite straight forward, I cut the doors and fitted small brass tube hinges, made the interior from lexan sheet, took a mould and then vacuum formed the engine detailing, which was then painted and some extra detail like plug wires fitted.

![]()

![]()

![]()

![]()

![]()

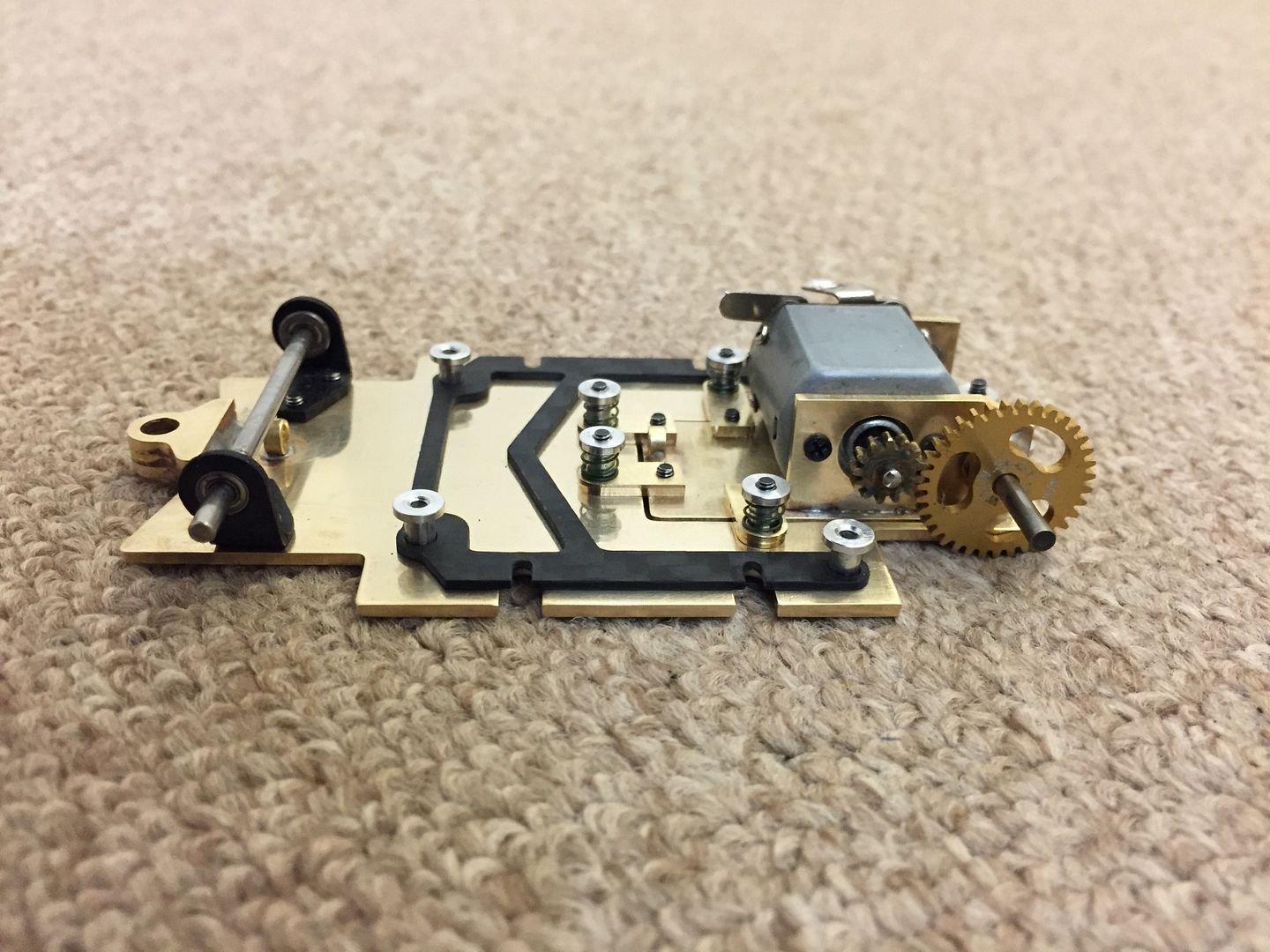

Decals were designed by Gary Skipp and printed by Colin Hughes, and were just great. The chassis was drawn in AutoCAD and milled in brass by Nick de Wachter, to hopefully keep the weight as low as possible.

![]()

I didn't get the chance to track test it before it was sent, so its been sitting mid-table in the competition. I think part of this is down to using the brass chassis which seriously pushes up the overall weight, when it returns, I will cut another in circuit board, and then use lead weight to fine tune the car.

Regards

Jon

I recently finished this build for the GVSCC Targa Florio proxy race, in Vancouver, Canada.

Im a huge fan of the Porsche 908/03, mainly because back in 2008, aged 14, I saw this build from Jairus Watson Here, and fell in love! Because of this build, I started to learn more about the Targa, and the men who risked everything to win.

When I read the rules for the proxy, this was the car I had to do. Firstly, I took a Fly Porsche, stripped it down and weighed it. With the bare body coming in at a hefty 20g, I took a mould, and cast a fibreglass body, weighing when cleaned up just 5grammes.

The rest of the build was quite straight forward, I cut the doors and fitted small brass tube hinges, made the interior from lexan sheet, took a mould and then vacuum formed the engine detailing, which was then painted and some extra detail like plug wires fitted.

Decals were designed by Gary Skipp and printed by Colin Hughes, and were just great. The chassis was drawn in AutoCAD and milled in brass by Nick de Wachter, to hopefully keep the weight as low as possible.

I didn't get the chance to track test it before it was sent, so its been sitting mid-table in the competition. I think part of this is down to using the brass chassis which seriously pushes up the overall weight, when it returns, I will cut another in circuit board, and then use lead weight to fine tune the car.

Regards

Jon